Industrial robots are widely used in various sectors as a crucial part of automation. They provide significant benefits to businesses with their advantages such as speed, precision, and repeatability in production processes. Ensuring the health and error-free operation of robots, particularly those involved in delicate tasks, is of utmost importance. Machine health monitoring plays a vital role in enabling industrial robots to operate smoothly, reducing the risk of malfunctions, and improving efficiency.

Industrial robots represent highly stressed production systems and their wear-related breakdown can lead to long production downtimes and thus to high costs. The most commonly used raw data for condition monitoring is the motor current or vibrations.Statistical moments such as mean, variance, skewness and kurtosis are typically used for the health indicators.

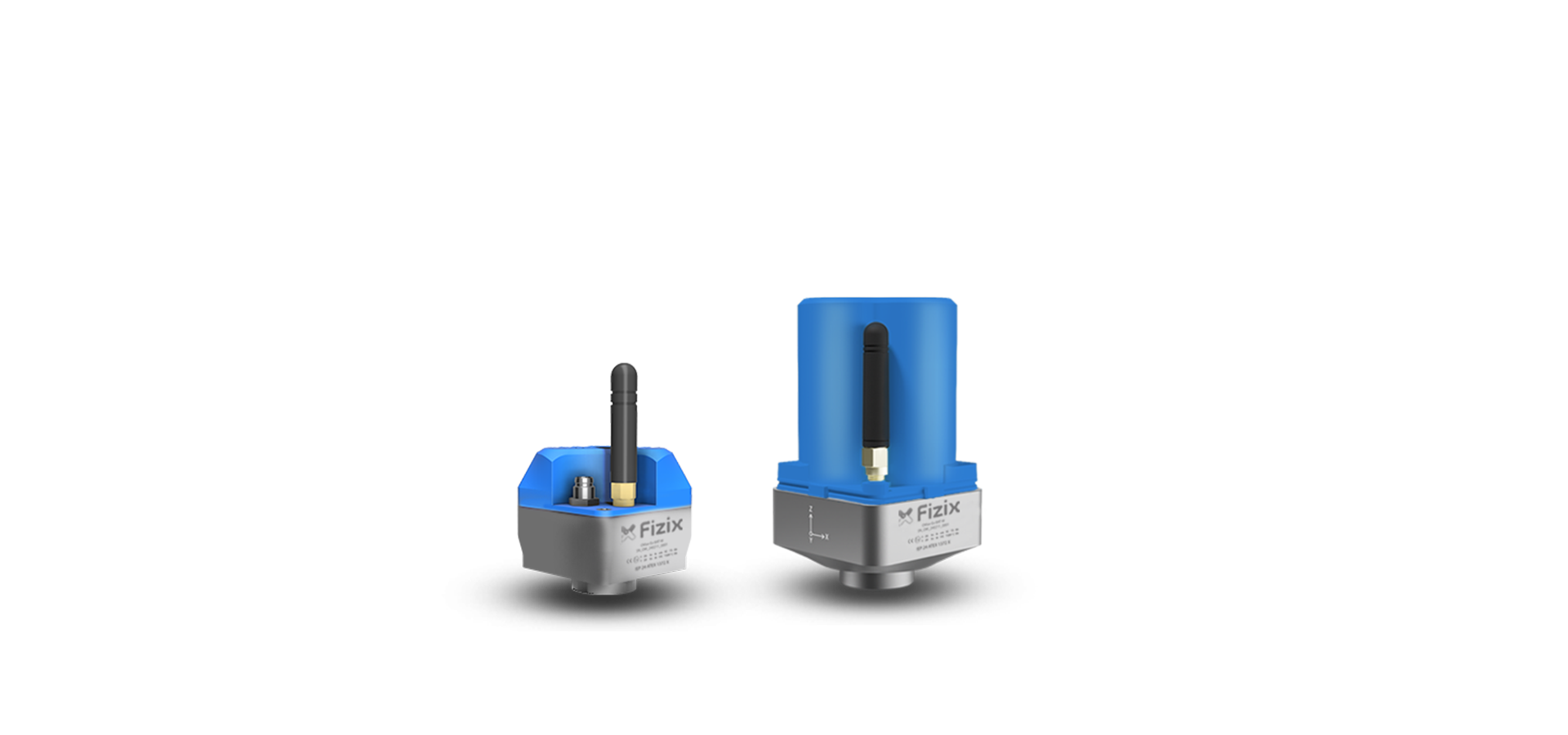

Gear surface degradation which happens because of mechanical wear and metallic debris build-up and bearing problems can be detected by Fizix’s smart sensors and AI algorithms.

Fizix online monitoring solutions provide predictive diagnostics and actionable machine health data that enable you to minimize unplanned outages, improve decision making, avoid OH&S incidents and extend the life of your critical assets.